Gantry Type

5-Axis High Speed Gantry Machining CenterG series

-5-axis simultaneous machining

-For mold machining

-U-shaped structure

-X/Y axis driven by linear motor

-Z-axis driven by double ball screws with innovative hollow water cooling technology

-For mold machining

-U-shaped structure

-X/Y axis driven by linear motor

-Z-axis driven by double ball screws with innovative hollow water cooling technology

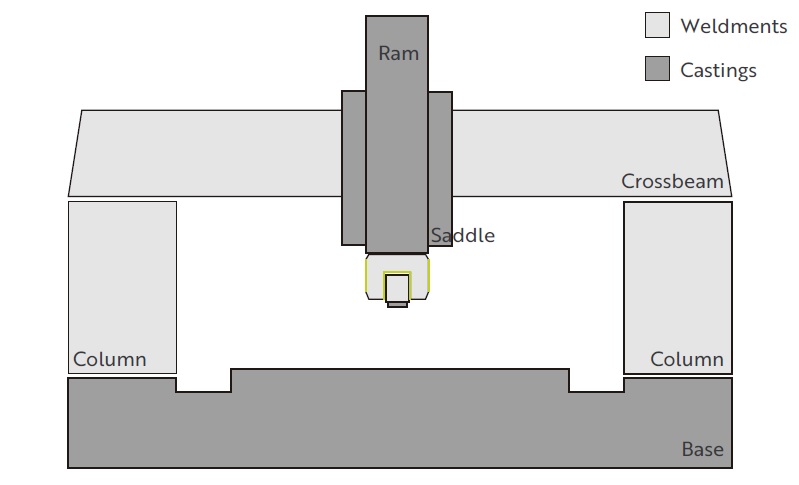

- U-shaped force flow structure

Casting-made saddle, ram and baseWith extremely high body stability, the machine has the best rigidity to ensure machining accuracy.

One-piece U-shaped and high rigid structure enhances long-term accuracy and stability thanks to the shortest transmission of the force flow and evenly distributed cutting force.

Ductile-iron-made ram

The ram is made by ductile iron for high rigidity and vibration damping. The machining accuracy and stability could be increased.

X/Y axis driven by linear motor

Linear motor provides excellent dynamics and static rigidity. The rapid feedrate of the axis is up to 60m/min and the acceleration is up to 0.5G ~ 0.7G. The structure is simple and easy to maintain without transmission power loss.

Z-axis driven by double ball screws with innovative hollow water cooling technology

Z-axis is driven by double ball screws which could ensure concentric of the moving part center and the weight center so that the vibration could be eliminated. Moreover, it is equipped with hollow water cooling system for precise temperature control and thermal deformation control.

Two-axis head driven by direct drive motor

Excellent surface finish contour could be enhanced thanks to the high torque direct drive motor system of two-axis heads.Small size appearance is suitable for complex curved surface machining and the advantages include low error, high resolution and high speed.

Optimized working area

Heightened column design provides larger Z-axis travels which is perfect for mold makers

*Please contact our sales if you have a special requirement.Specification Unit G2520/40/50/60/80 G3020/40/50/60/80 X-axis mm 2,000/4,000/5,000/6,000/8,000 2,000/4,000/5,000/6,000/8,000 Y-axis mm 2,500 3,000 Z-axis mm 1,000 1,000 Table Length mm 2,000/4,000/5,000/6,000/8,000 2,000/4,000/5,000/6,000/8,000 Table Width mm 2,580/2,500/2,500/2,500/2,500 3,000 MAX. Table load kg/m² 8 Rapid traverse m /min XY=60 Z=40 X.Y.Z axis acceleration m/sec² 5 Spindle taper HSK63A Spindle speed rpm 24,000 Spindle power

( S 1 / S6)kW 35/42 Spindle torque

( S 1 / S6)Nm 55.6/67.2 Recommended 2-axis head Mono Support Milling Head Swivel/Rotation Torque Nm A=529/869

C=783/1,300Swivel/Rotation Speed rpm A=C=30(cont)/60(max) Swivel/Rotation Angle deg A=±125° C=±360° Clamping Torque Nm A=4,000 C=4,000 Tool shank pcs 30T Max. tool length mm 300 Max. tool diameter with

adjacent toolmm Ø75 Max. tool diameter

without an adjacent toolmm Ø150 Weight tons. 35-65

*All specifications and designs are subject to change without notice.