Gantry Type

5-axis Gantry Vertical Machining CenterG800-TR series

-Rapid traverse could reach 48m/min

-High rigidity U-frame structure

-Milling and turning compound machining (optional)

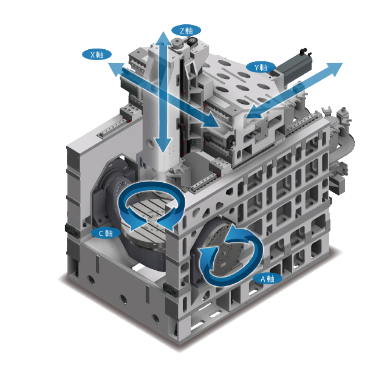

Three-axis is driven at center of gravity(DCG)The driven centers of the three-axis are all on these gravity centers, which greatly improves the dynamic stability of the structure.

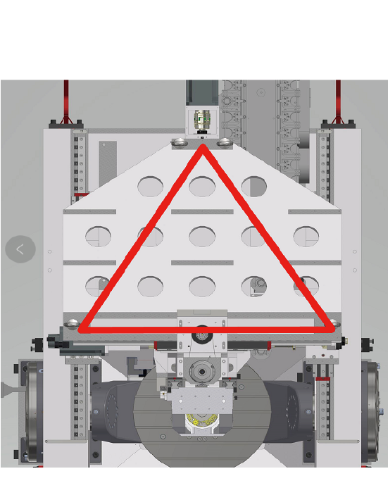

Compact trunnion rotary table

X/Y/Z axis moving and table rotation are working individually to make sure machining is free from 3 axis inertia influences. The perfect servo-driven design gives excellent machining stability.

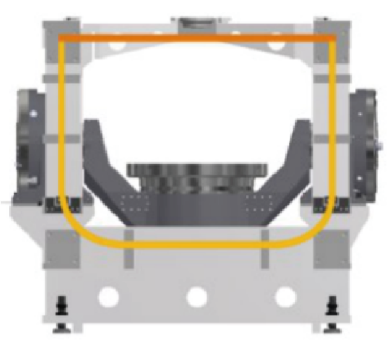

High rigidity U-frame structure

The saddle and column form a closed structure. High rigidity machines could reduce vibration effectively, increase processing stability and improve machining accuracy.

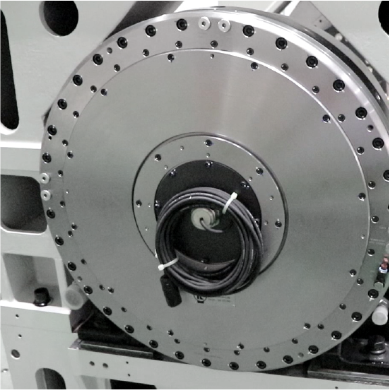

The Direct-Drive Motor directly drives the rotary table to provide high-precision machining.

The A / C axis are driven by direct-drive motors. The power can be completely transmitted and provides high-precision machining capabilities.

*Please contact our sales if you have a special requirement.Specification Unit G800-TR G800T X-axis mm 800 Y-axis mm 830 Z-axis mm 560 A-axis deg ±120 C-axis deg ±360 A-axis torque(S1/max) Nm 4,240/6,920 4,240/6,920 C-axis torque(S1/max) Nm 2,120/3,460 1,490/2,460 Rapid traverse m /min XYZ=48 X.Y.Z axis acceleration m/sec² 4 Spindle taper HSK63A HSK63T Spindle speed rpm 20,000 20,000 Spindle power

( S1 / S6)kW 20/24 20/23 Spindle torque

( S1 / S6)Nm 45.5/55 85/99 Tool shank pcs 32T Max. tool length mm 300 Max. tool diameter with

adjacent toolmm Ø75 Max. tool diameter

without an adjacent toolmm Ø120 Weight tons. 15.5

*All specifications and designs are subject to change without notice.