Bridge Type

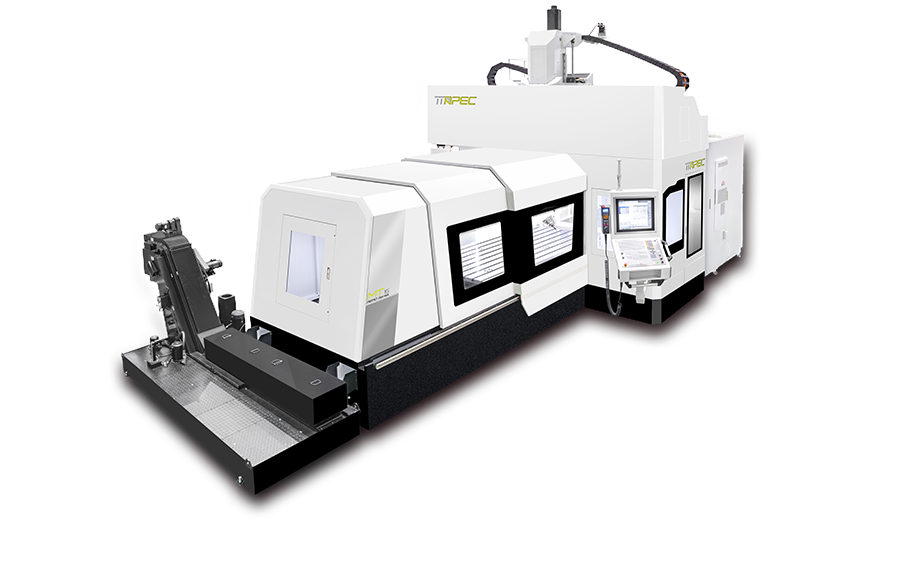

5-axis High Speed Double Column Machining CenterMT15 series

-5-axis simultaneous machining

-Suitable for aerospace aluminum alloy structural parts machining/High-precision mold processing

-Duo block structure design

-X/Y/Z axis driven by high-speed ball screws

-Suitable for aerospace aluminum alloy structural parts machining/High-precision mold processing

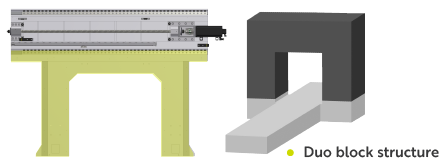

-Duo block structure design

-X/Y/Z axis driven by high-speed ball screws

- Larger machining area

Duo block structure designMachine rigidity and working stability could be enhanced via duo block structure design.

Despite the smallest footprint in its class, this compact model features a wide machining area and complete functions.

High dynamics

3-axis with high acceleration and deceleration, especially suitable for multiple bulkheads of aluminum alloy material processing.

Fully enclosed splash guard

Lower noise and prevent spreading of chips and coolant liquid.

Driven by high-speed ball screw

X/Y/Z-axis are driven by double ball screws which could ensure the concentric of the moving part center and the weight center so that the vibration could be eliminated.

Cross beam flushing system (Only for aerospace)

High pressure pump with groups of powerful nozzles can quickly remove the chips.

*Please contact our sales if you have a special requirement.Specification Unit MT1520/1530 X-axis mm 2,000/3,000 Y-axis mm 2,000 Z-axis mm 850 Table Length mm 2,100/3,100 Table Width mm 1,200 MAX. Table load tons 3/5 Rapid traverse m /min XYZ=30* X.Y.Z-axis acceleration m/sec² 5 Spindle taper HSK63A Spindle speed rpm 24,000 Spindle power

( S 1 / S6)kW 35/42 Spindle torque

( S 1 / S6)Nm 55.6/67.2 Recommended 2-axis head Fork Type Milling Head Swivel/Rotation Torque Nm A=529/869

C=783/1,300Swivel/Rotation Speed rpm A=C=30(cont)/60(max) Swivel/Rotation Angle deg A=±125° C=±360° Clamping Torque Nm A=4,000 C=4,000 Tool shank pcs 32T Max. tool length mm 300 Max. tool diameter with

adjacent toolmm Ø75 Max. tool diameter

without an adjacent toolmm Ø130 Weight tons. 20/24

*All specifications and designs are subject to change without notice.