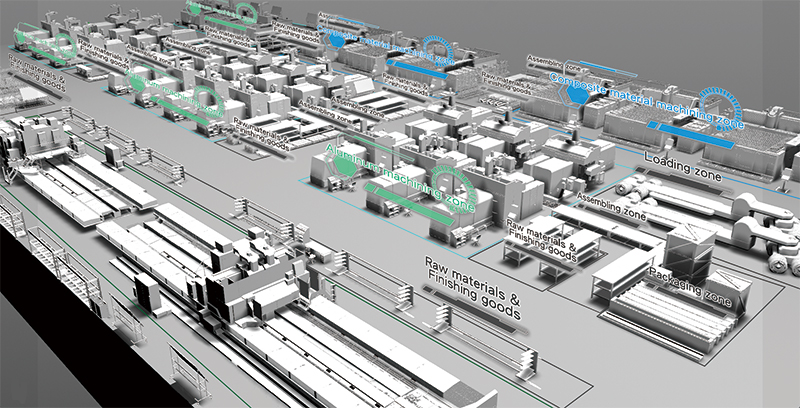

Factory Planning

In order to optimize customers' invested resources and capital so that their competiveness in aerospace supply chain could be improved, APEC provides comprehensive Factory Planning Services for them.

The services include production requirement analysis, production line utilization analysis, machine layout planning and machining process optimization.

1. Analyze current/future production requirement

Firstly, APEC team will analyze carefully about customers' current production processes and future requirements. It is an important procedure to acknowledge customers' existing equipment/software/the level of digitalization/future machining demands (target, quantity...). After the analysis, we could come up with the initial plan to discuss with customers.

2. Analyze production line utilization After understanding customers' targeted machining workpieces, APEC team would then analyze production line utilization. The optimum production strategy would be formulated to fulfill the needs.

Customers' competitiveness could be improved accordingly.

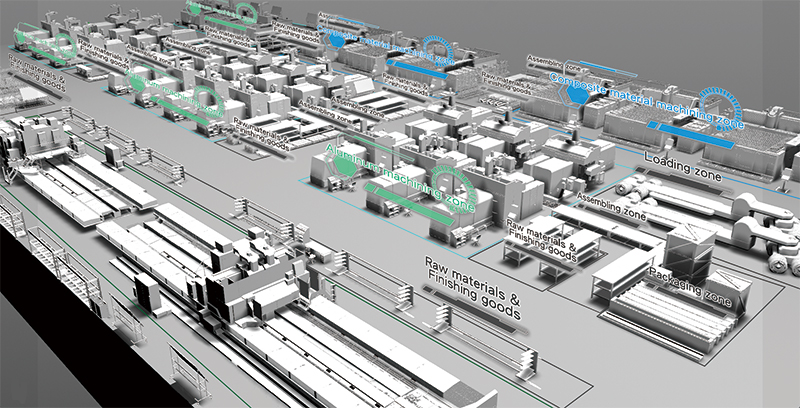

The services include production requirement analysis, production line utilization analysis, machine layout planning and machining process optimization.

1. Analyze current/future production requirement

Firstly, APEC team will analyze carefully about customers' current production processes and future requirements. It is an important procedure to acknowledge customers' existing equipment/software/the level of digitalization/future machining demands (target, quantity...). After the analysis, we could come up with the initial plan to discuss with customers.

2. Analyze production line utilization After understanding customers' targeted machining workpieces, APEC team would then analyze production line utilization. The optimum production strategy would be formulated to fulfill the needs.

- Machine cycle time

- Non-processing time

- Maximum daily production capacity per machine

- Monthly/Annual production capacity

- Suitable machine suggestions

- OEE( Overall Equipment Effectiveness)

- Plan the future layout/ machine requirement

- Optimize machining processes

Customers' competitiveness could be improved accordingly.