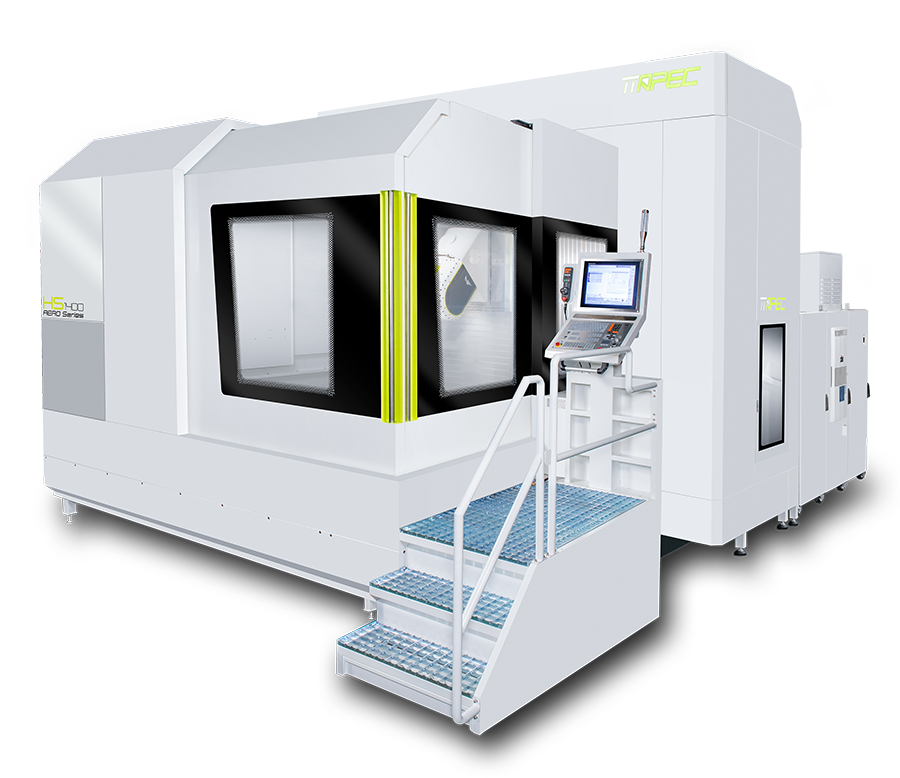

Horizontal Type

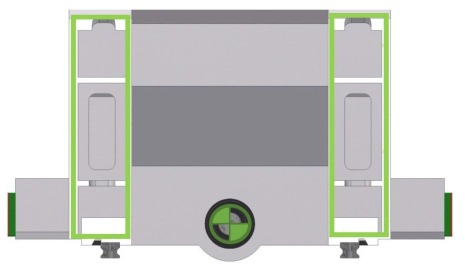

5-axis Horizontal Machining CenterHS1400

-High rigidity T-shaped structure design

-Double-wall and symmetrical structure design

-X/Y/Z-axis driven by high-speed ball screw

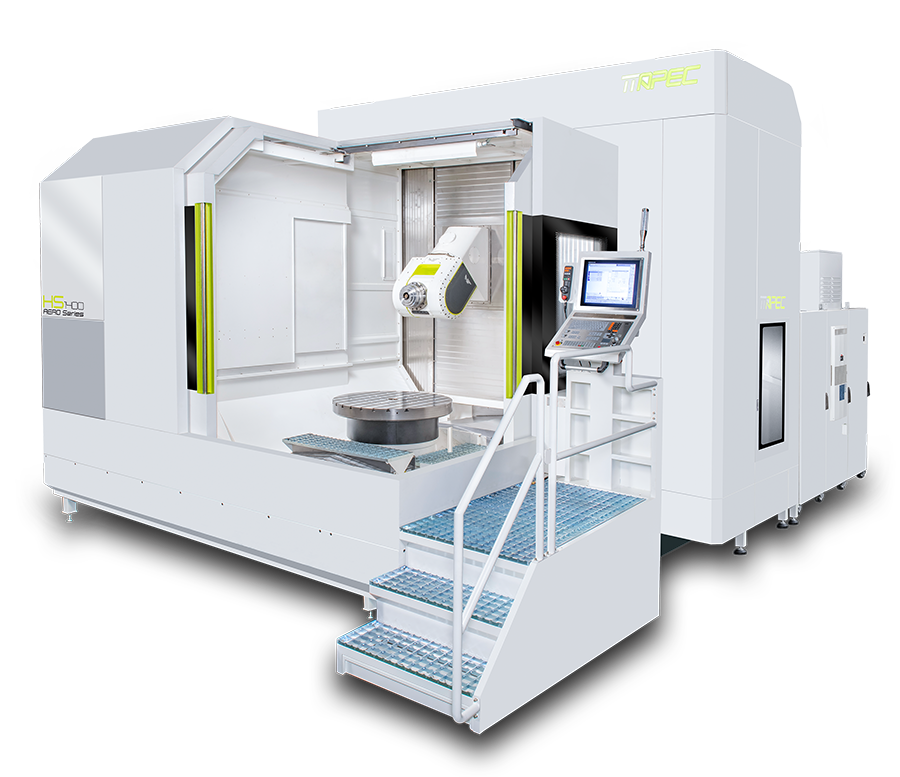

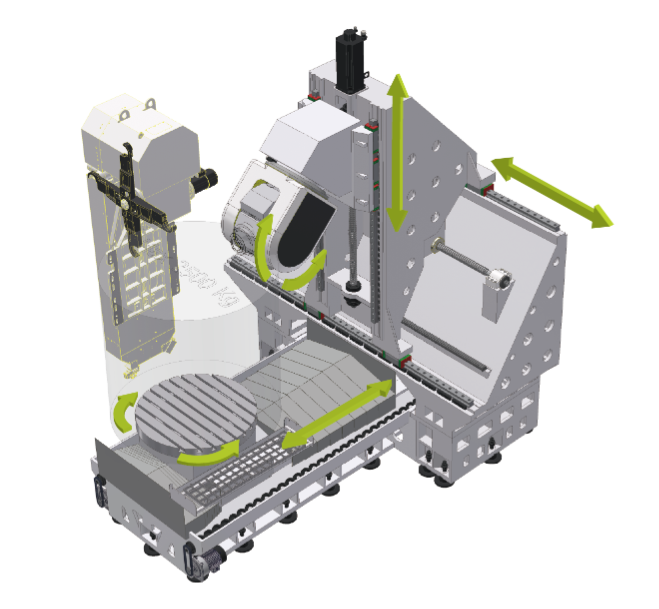

45° degree saddle design

The saddle is designed with a 45-degree angle and matched with a fork-type head, the machine can achieve more angles of cutting range.

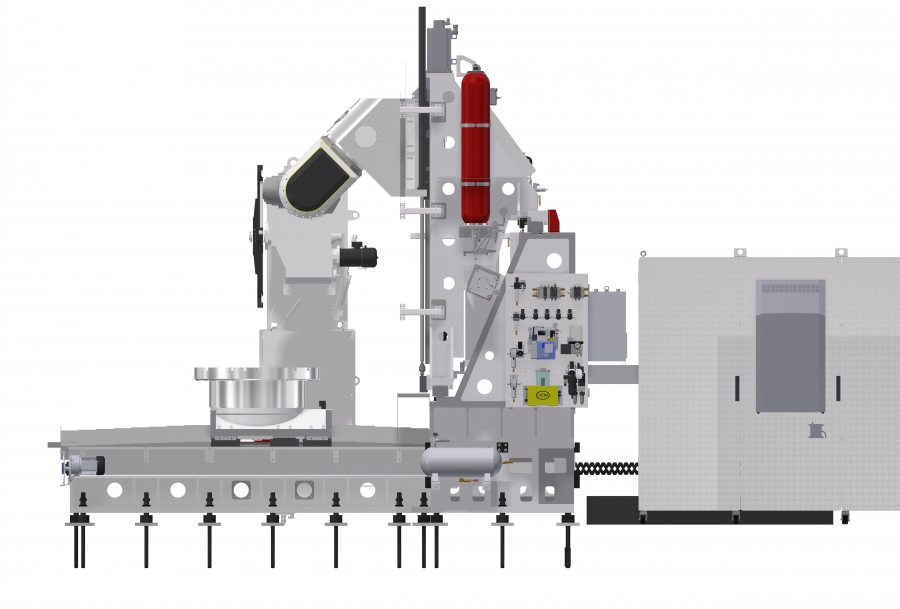

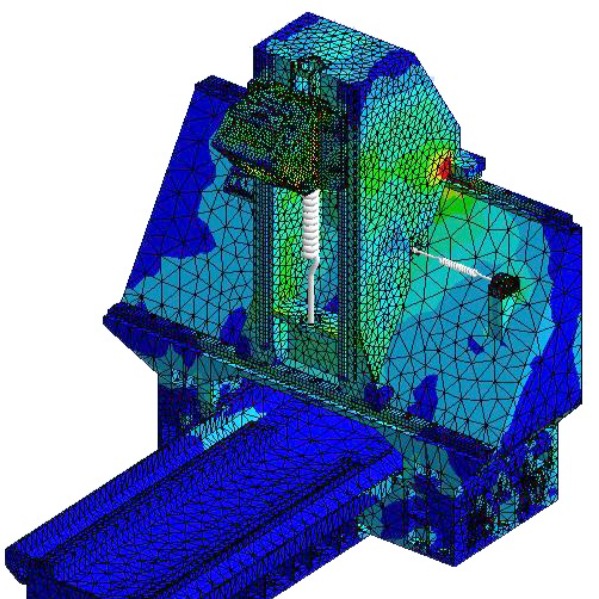

THE SHORTEST FORCE FLOW BED DESIGN

The ribb ed s tructure of the b ottom b ed is V-shaped ribs to make the s tructure s trong and ensure pro cessing s tability. The shor test configuration of the force flow between the guide rail and the anchor bolts meets the demand for high rigidity.

Double-wall structure designed column

Increase the structure rigidity and to minimize the

possibilities of thermal deformation.

The base structure is optimized through Finite Element Analysis (FEA)

The X-axis adopts a high and low r ail design. The L 1

size is larger than other indus try and driving the

center of gravity is closer to the tool tip point, which

improves rigidity and stability. It is suitable for

processing difficult-to-cut materials and achieves

perfect cutting dynamic characteristics.

*Please contact our sales if you have a special requirement.Specification Unit HS1400 X-axis mm 1,450 Y-axis mm 1,200 Z-axis mm 1,300 B-axis torque(S1/max) mm 2,134/3,777 X.Y.Z axis acceleration m /min XYZ=50 Spindle taper HSK100A Spindle speed rpm 12,000 Spindle power

( S 1 / S6)kW 50/76 Spindle torque

( S 1 / S6)Nm 200/302 Tool shank pcs 40T Max. tool length mm 400 Max. tool diameter with

adjacent toolmm Ø125 Max. tool diameter

without an adjacent toolmm Ø250 Weight tons. 25

*All specifications and designs are subject to change without notice.