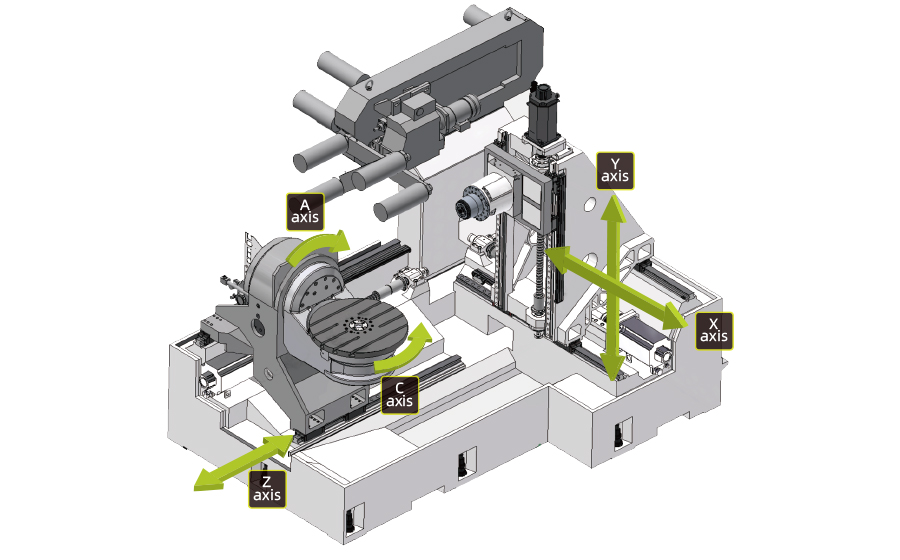

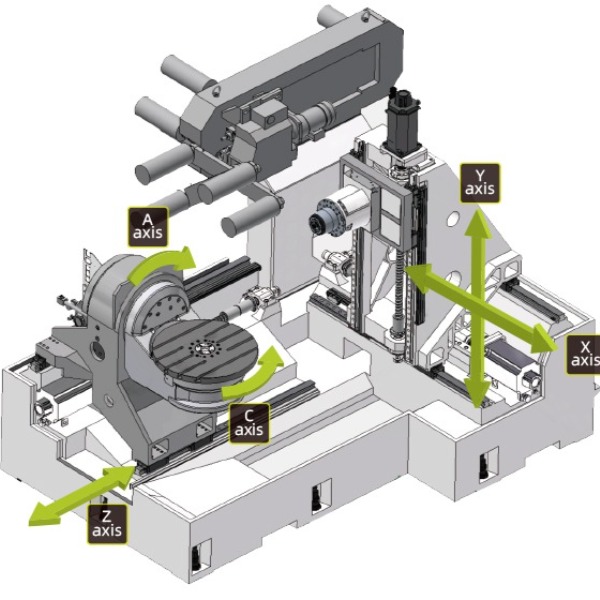

Horizontal Type

5-axis Horizontal Machining CenterHS700

-High rigidity T-shaped structure design

-X/Y/Z-axis driven by high-speed ball screw

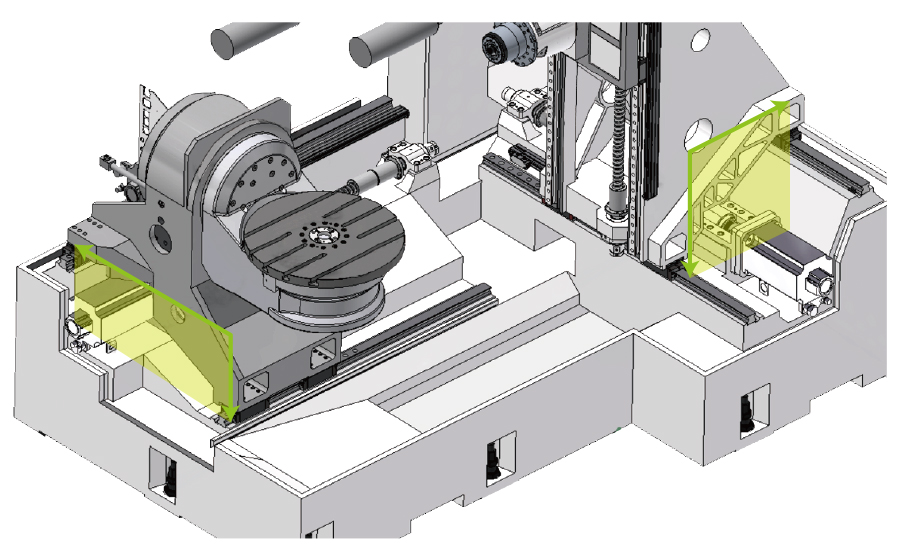

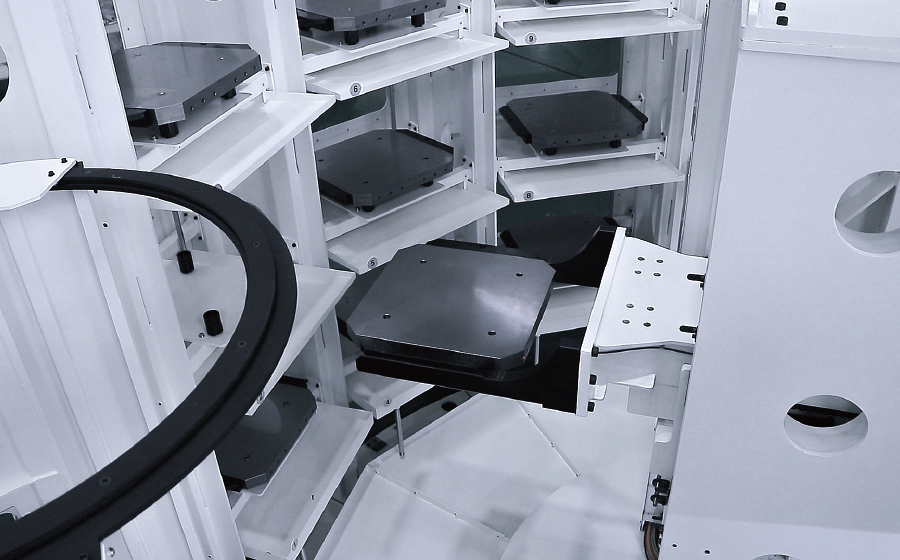

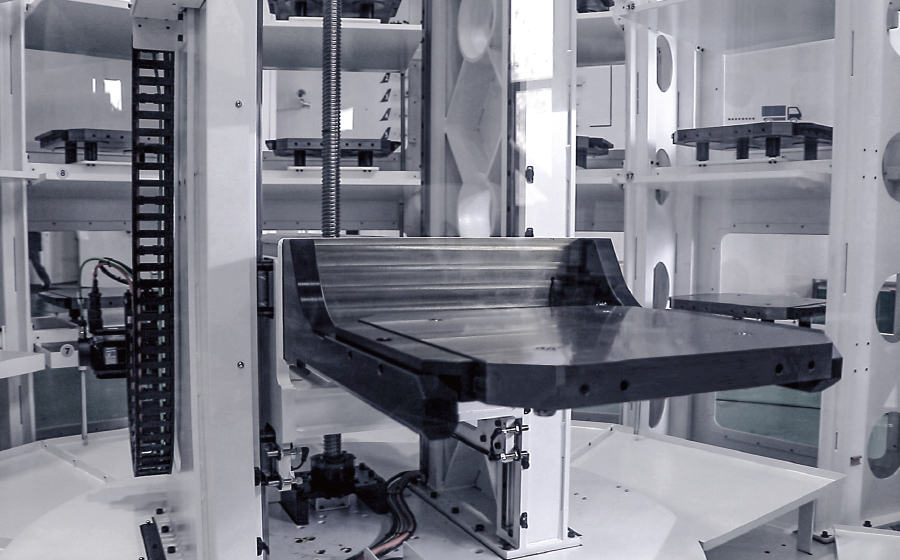

-Multi-Pallet Pool system (opt.)

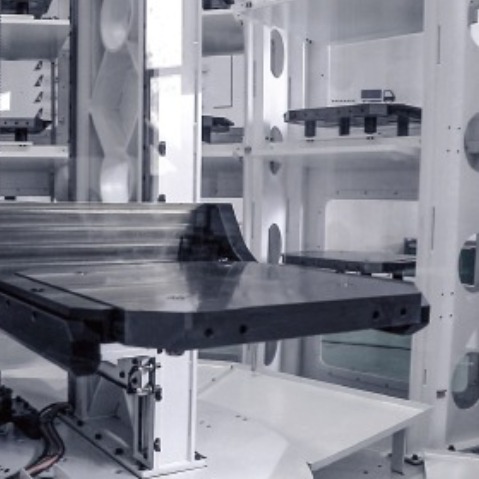

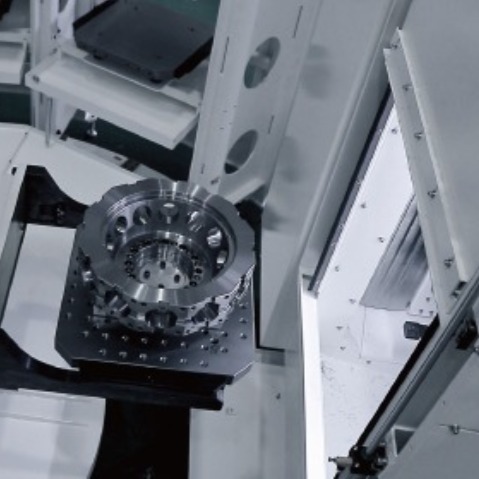

Multi-Pallet Pool system (opt.)

The Multi-Pallet Pool (MPP) system uses a zero clamp system for more

precise exchange motion. The MPP system can carry out the loading and

unloading operation of the workbench in advance, saving unnecessary time and improving the effective utilization rate of the machine. There are 6, 12,and 18 options for the pallet pool.

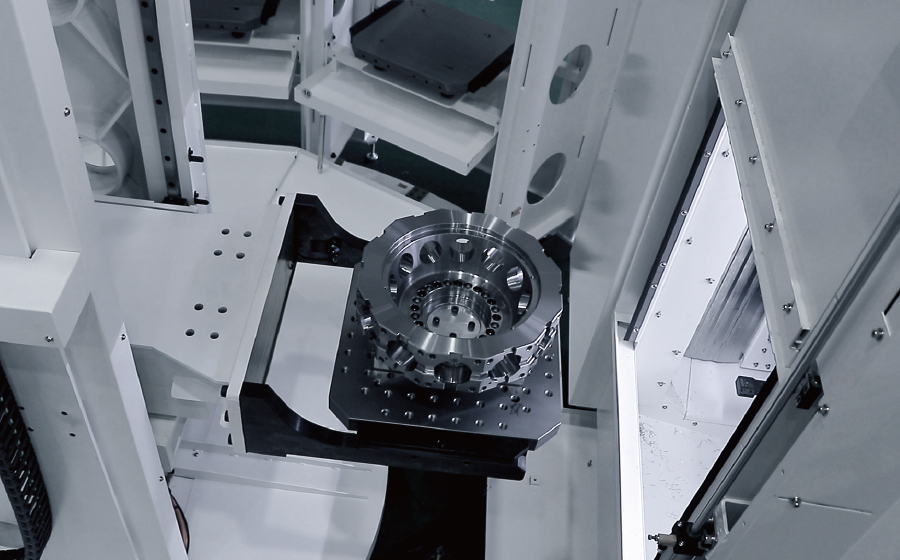

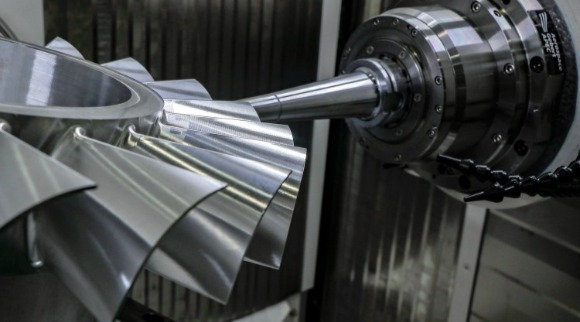

High rigidity T-shaped structure design

Inverted dual V-shaped rib structure applied in basement design to

achieve b est force flow path. The whole travel of X -axis is supported,

and this is to avoid gravitational dropping and deformation to guarantee

workpiece and surface machining accuracy.X-axis and Z-axis of bed are high and low rail design

The center of gravity is more advanced than others, and the cutting dynamics are better.

Double-wall and symmetrical structure design

The column adopts a double-wall structure design to increase the structure's rigidity and minimize the possibility of thermal deformation.

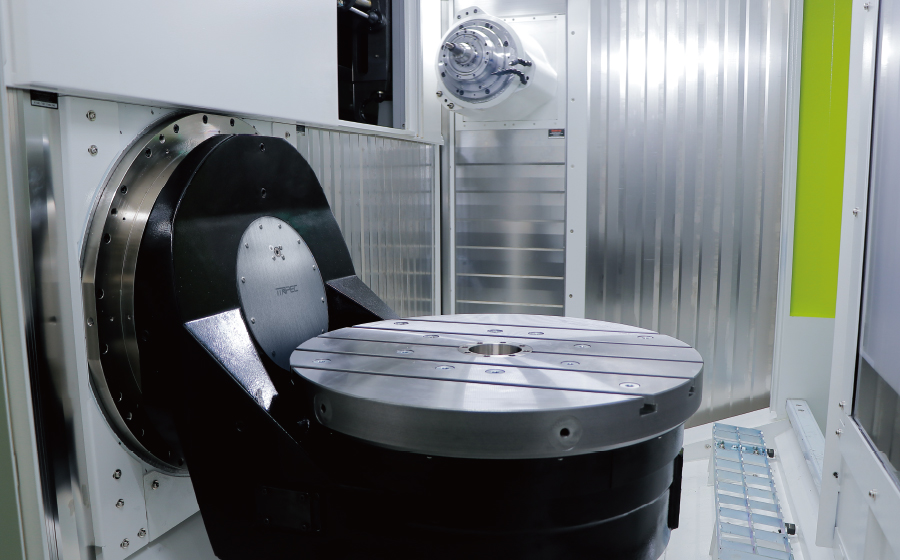

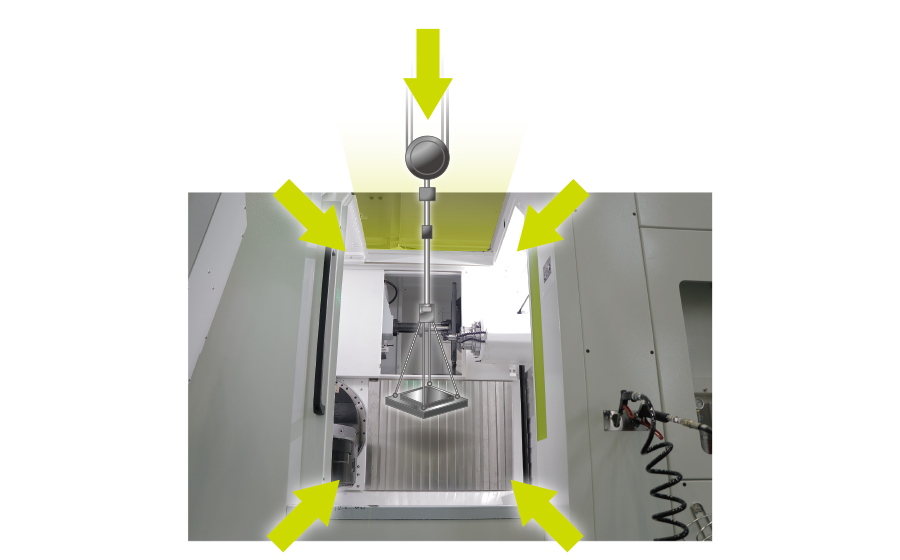

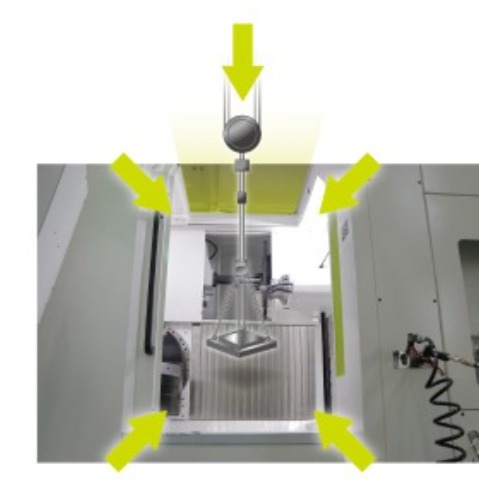

Operation / Accessibility

Easily reachable distance to working table

and widely door open space is convenient

for loading/unloading

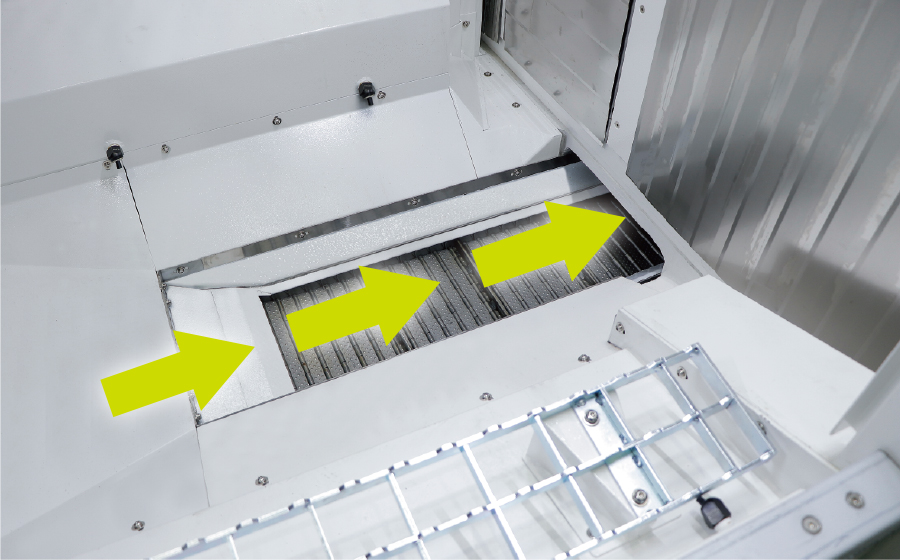

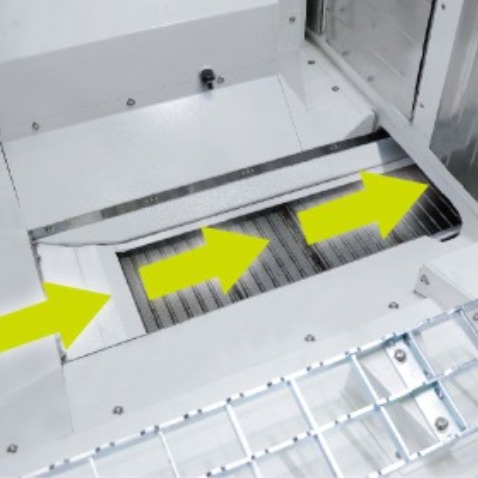

Well chip flow

Central chip flow design. Chips can be carried out immediately while machining.

It prevents casting structure from being affected by hot chips and maintains machining accuracy.

Open-top telescopic cover

Wide door opening facilitates operation and

maintenance.

*Please contact our sales if you have a special requirement.Specification Unit HS700 X-axis mm 710 Y-axis mm 910 Z-axis mm 810 Feedrate m /min XYZ=60 Table size ( Diameter ) mm Ø650 Max. processing diameter mm Ø700 Max. table load kg 350 Max. rotation angle deg A=-90~135

C=±360Max. rotation speed rpm A=70

C=80Torque ( S 1 / Max. ) Nm A=2,134/3,777

C=672/1,210Spindle taper HSK63A Spindle speed rpm 20,000 Spindle power( S 1 / Max. ) kW 20/24 Spindle torque( S 1 / Max. ) Nm 45.5/55 Tool shank pcs 32T Max. tool length mm 400 Max. tool diameter with adjacent tool mm Ø75 Max. tool diameter without adjacent tool mm Ø130

*All specifications and designs are subject to change without notice.