Gantry Type with Box-in-Box

5-axis High Speed Gantry Machining CenterGM series

-For mold machining

-Box-in-Box structure design enhances machine rigidity and ensures the best accuracy performance for high-speed processing

-X/Y/Z-axis driven by linear motor

-Heightened column design for optimized working area

Box-in-Box structure design enhances machine rigidity and ensures the best accuracy performance for high-speed processing

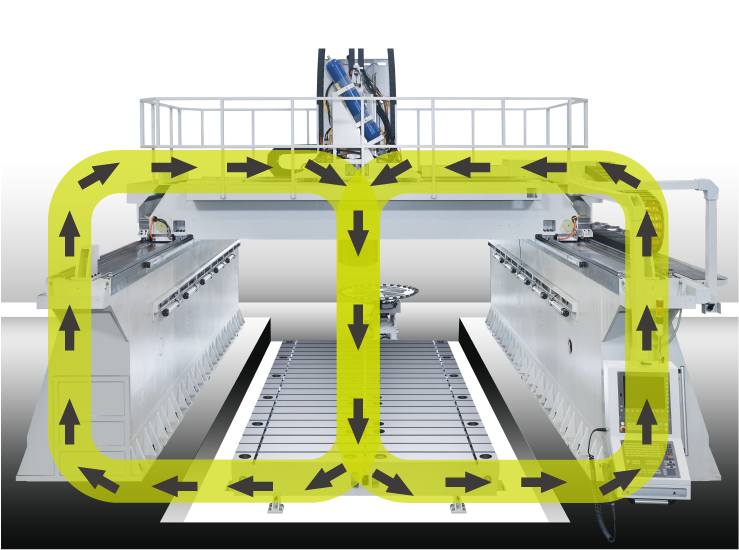

The crossbeam and saddle are designed as box-in-box thermal symmetrical structure which gives good force flow transmission and prevents deflection.

With perfect structural rigidity, the machine gives the best accuracy performance of high-speed machining and reduces thermal deformation and weight deformation greatly.

Symmetrical force flow designX/Y/Z axis are designed with symmetric force structure .Dual driving units and equivalent uniform force at gravity center can ensure optimal surface quality and prolong tool life.

X/Y/Z axis driven by linear motor

X/Y/Z axis driven by linear motor

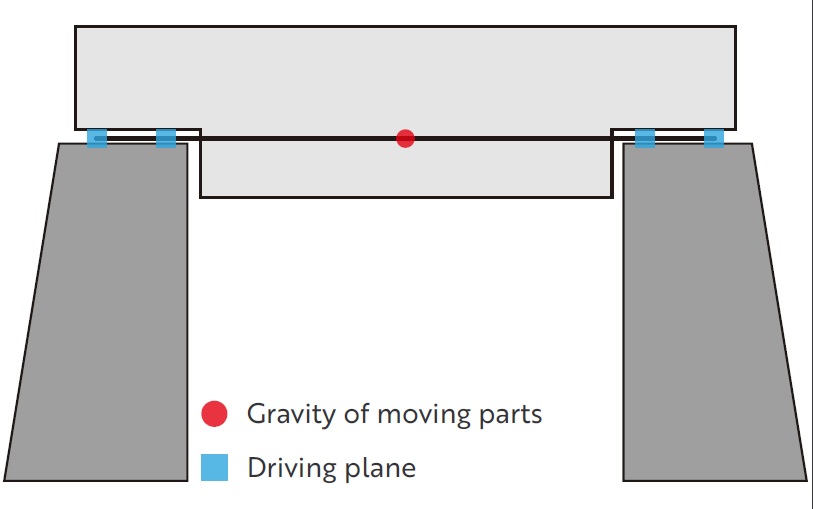

The lowest gravity center in the worldZero distance between gravity of the moving parts and the driving plane makes the gravity center closer to the driving plane. The machine stability could then be improved and the best machine rigidity could be ensured.

X/Y/Z axis driven by linear motor provides excellent dynamics and static rigidity. The rapid feedrate of the axis is up to 60m/min and the acceleration is up to 0.5G ~ 0.7G. The structure is simple and easy to maintain without transmission

power loss.

Two-axis head driven by direct drive motor

Excellent surface finish contour could be enhanced thanks to the high torque direct drive motor system of two-axis heads.Small size appearance is suitable for complex curved surface machining and the advantages include low error, high resolution and high speed.

Counterbalance system

The counter balance system is designed with close-loop which include high pressure components. This system could compensate the gravity effect and minimize the load of the motor. Excellent static and dynamic rigidity could be ensured.

Optimized working area

Heightened column design provides larger Z-axis travels which is perfect for mold makers

*Please contact our sales if you have a special requirement.Specification Unit GM2530/40/50/60/80 GM3240/50/60/80 GM4050/60/70/80 X-axis mm 3,000/4,000/5,000/6,000/8,000 4,000/5,000/6,000/8,000 5,000/6,000/7,000/8,000 Y-axis mm 2,500 3,200 4,000 Z-axis mm 1,000 Table Length mm 4,000/5,000/6,000/8,000 4,000/5,000/6,000/8,000 5,000/6,000/7,000/8,000 Table Width mm 2,500 3,000 3,800 MAX. Table load kg/m² 8,000 Rapid traverse m /min XYZ=60 X.Y.Z axis acceleration m/sec² 5-8 Spindle taper HSK63A Spindle speed rpm 24,000 Spindle power kW 35/42 Spindle torque Nm 55.6/67.2 Recommended 2-axis head Fork Type Milling Head Swivel/Rotation Torque Nm B=1,192/1,980

C=1,050/1,740Swivel/Rotation Speed rpm B=C=30(cont)/60(max) Swivel/Rotation Angle deg HSK63A:B=±120° C=±360°

HSK100A:B=±115° C=±360°Clamping Torque Nm B=4,000 C=4,000 Tool shank pcs 20T Max. tool length mm 300 Max. tool diameter with

adjacent toolmm Ø150 Max. tool diameter

without an adjacent toolmm Ø180 Weight tons. 84

*All specifications and designs are subject to change without notice.