Bridge Type

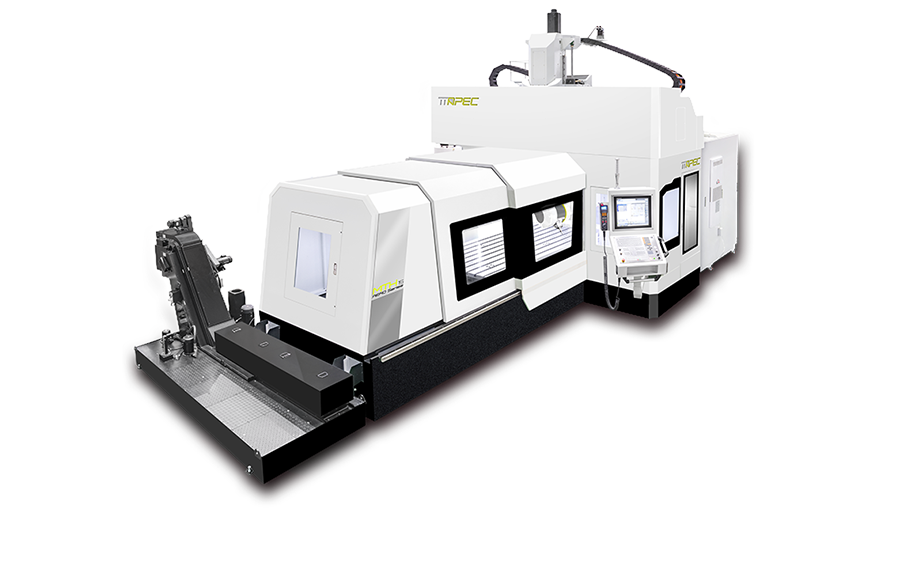

5-axis High Speed Double Column Machining CenterMTH15 series

-Suitable for aerospace titanium alloy processing

-Specially design saddle and ram for heavy-duty machining

-Duo block structure design

-Specially design saddle and ram for heavy-duty machining

-Duo block structure design

- Specially designed saddle and ram for heavy-duty machining

MTH enlarges the size of the head from 400mmX450mm to 540mmX540mm. Machining stability could be enhanced by increasing the sectional area.

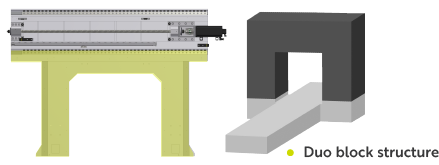

Duo block structure design

Strengthened MTH machine structure could provide machine rigidity for hard-to-cut material machining.

Powerful driving system

Servo motor and ball screws are specially equipped for heavy-duty machining.

High torque 2-axis milling head

Equipped with high rigidity and high torque 2-axis head. Spindle torque could be up to 400 Nm.

*Please contact our sales if you have a special requirement.Specification Unit MTH1530 X-axis mm 3,000 Y-axis mm 2,000 Z-axis mm 850 Table Length mm 3,100 Table Width mm 1,200 MAX. Table load tons 5 Rapid traverse m /min XYZ=30 X.Y.Z-axis acceleration m/sec² 5 Spindle taper HSK100A Spindle speed rpm 12,000 Spindle power(S1/S6) kW 50/62.5 Spindle torque(S1/S6) Nm 318/398 Recommended 2-axis head Fork Type Milling Head Swivel/Rotation Speed Nm B=1,344/2,420

C=1,610/2,940Swivel/Rotation Torque rpm B=C=30(cont)/60(max) Swivel/Rotation Angle deg B=±120° C=±360° Clamping Torque Nm B=6,000 C=6,000 Tool shank pcs 32T Max. tool length mm 400 Max. tool diameter with

adjacent toolmm Ø125 Max. tool diameter

without an adjacent toolmm Ø250 Weight tons. 27

*All specifications and designs are subject to change without notice.